Digital twin simulations—high-fidelity, living models of vehicles, factories, and workflows—are reshaping how cars are conceived, built, and verified. In 2025, automaker design studios are using them to iterate on surfaces and fit-and-finish with the same care a sculptor brings to clay, while production teams trial robot choreography and tooling virtually before metal is cut. Museums and design institutions are beginning to showcase these visual systems to broader audiences, helping demystify how craft and code now intersect on the factory floor. The immediate result is fewer surprises during launch, tighter quality loops, and a clearer thread between the artist’s intent in the studio and the car customers experience on the road.

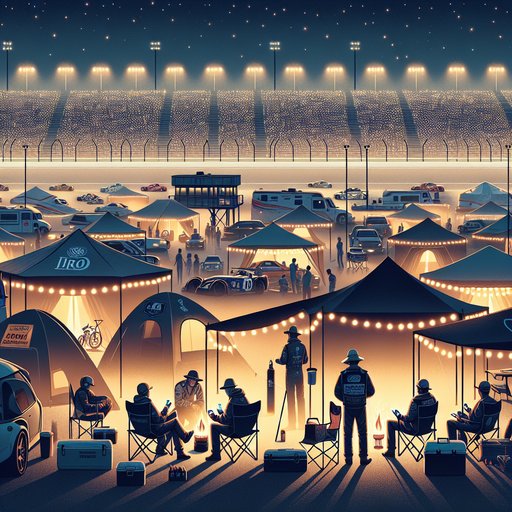

Endurance racing invites fans to participate as much as spectate, turning each June at Le Mans and every January at Daytona into round-the-clock festivals. Supporters build temporary villages, follow strategy live, and meet drivers during pit walks and autograph sessions. Whether trackside at Spa or Fuji, or tuned in from afar with timing apps and radio, fans shape the rhythm of the marathon. Their rituals, technology, and community traditions knit together the culture of WEC and IMSA, season after season.

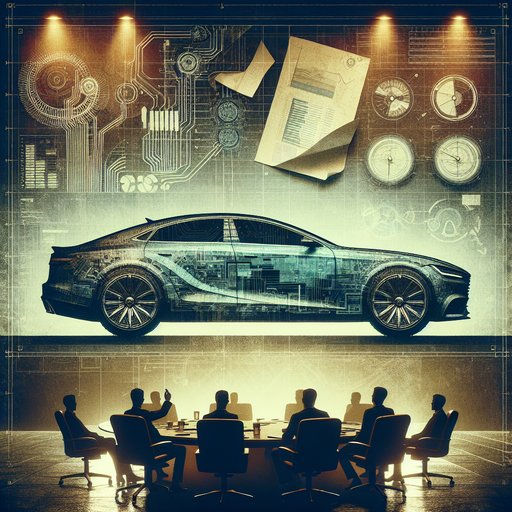

Before the headlines and hearings, the scandal took shape in meeting rooms where marketing promises outran physics, and in lab cells where tidy curves hid messy realities. In 2015, the Volkswagen diesel emissions crisis broke wide open, but its roots reached back through a decade of policy incentives, engineering compromises, and a belief that software could reconcile the irreconcilable. What followed reconfigured regulatory playbooks on both sides of the Atlantic and recast how drivers, dealers, and lawmakers think about trust in a world where cars are as much code as metal.

Battery-electric and hydrogen-powered cargo trucks are crossing key thresholds, turning demonstrations into daily duty. On the electric side, megawatt-class charging is moving from lab tests to depot pilots, and long-haul tractors like Mercedes‑Benz’s eActros 600 and new-generation models from MAN, Volvo, and Scania are entering customer trials with ranges fit for regional and corridor freight. Hydrogen programs are scaling, too: Daimler Truck’s liquid hydrogen GenH2 proved 1,000‑plus kilometers on a single fill, while Hyundai, Toyota–PACCAR, and Nikola expanded fuel-cell deployments for drayage and regional haul. Paired with fresh rules in Europe and U.S. state-level mandates, infrastructure buildouts are giving fleets clearer paths to cut emissions without surrendering payload or uptime.