Tires are the only part of a Formula 1 car that touch the track, and that thin contact patch has steered the sport’s technical direction, strategy, and spectacle for decades. From the fierce Bridgestone–Michelin rivalry of the early 2000s to Pirelli’s era of engineered degradation, rubber chemistry and construction have shaped how drivers attack, how teams plan, and how championships are won. Rule changes around slicks and grooves, temperature limits, and compound allocation are not background details; they are central to how modern F1 races unfold. Understanding tires is understanding how F1 evolved from flat‑out sprints to a chess match of grip management, pit windows, and split‑second decisions.

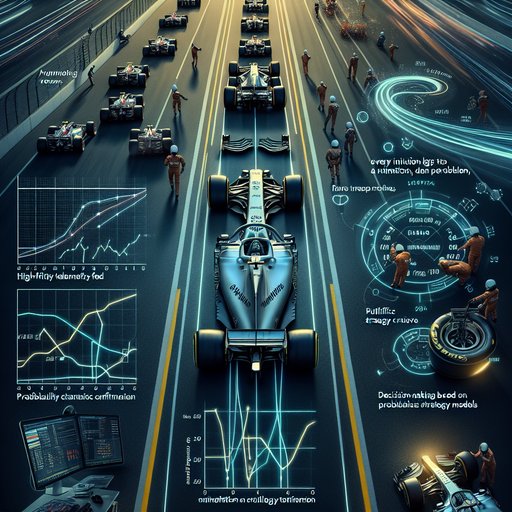

Formula 1’s transformation from intuition-led pit walls to analytics-driven decision centers is one of modern sport’s defining shifts. Live telemetry, high-fidelity tire monitoring, and probabilistic strategy models have turned every lap into a rolling optimization problem, where milliseconds and megabytes carry equal weight. The result is not just better-informed choices, but a new rhythm to races themselves—stint lengths flex to real-time degradation curves, pit windows open and close with traffic forecasts, and rain calls hinge on model confidence rather than gut feel. This evolution did not happen overnight; it grew from early data loggers into a tightly integrated ecosystem of sensors, software, and specialists that now shapes almost every move on track.

Formula 1’s broadcast journey mirrors the sport’s technological arc: from sporadic, grainy coverage to a global, data-rich experience that places fans virtually inside the cockpit. Over seven decades, innovations like onboard cameras, live telemetry, stabilized aerial shots, and interactive streaming have transformed how stories are told and races are understood. Today’s world feed blends engineering, cinematography, and real-time analytics to deepen comprehension of strategy and skill, inviting audiences to engage with the sport at an unprecedented level. Tracing that evolution reveals how broadcasting did more than show races; it reshaped the narrative of F1 and expanded its audience.

Across global supply chains, manufacturers are pairing meticulous energy efficiency measures with a rapid shift to renewable power, turning utility bills into a source of competitive advantage. Volatile fuel prices, tightening carbon policies, and customer demand for low‑carbon products have pushed energy from a back‑office expense to a board‑level priority. The response blends disciplined, data‑driven housekeeping with transformative changes to heat and power. From motors and steam systems to on‑site solar and long‑term power contracts for wind, the toolkit is now practical, financeable, and widely proven. The result is a quieter revolution on factory floors: less waste, lower costs, and falling emissions without sacrificing output or quality.