Heavy-duty trucks are rolling out a new safety stack that is already reshaping accident statistics and driver workloads. From automatic emergency braking and blind-spot detection to direct-vision cabs and AI-driven driver monitoring, systems once confined to pilot programs are now standard kit on long-haul tractors and urban rigids. In the EU, mandates that took effect in July 2024 are accelerating adoption, while U.S. fleets lean on proven systems such as electronic stability control and increasingly spec forward-collision tech. Insurers and shippers say the improvements are reducing claims, downtime, and near-miss events in busy freight corridors. The next wave—vehicle-to-everything alerts and smarter trailer integration—promises to widen the safety net without slowing freight.

Regulation is setting the pace. The EU’s General Safety Regulation requires new heavy vehicle types to include automatic emergency braking, intelligent speed assistance, driver attention warnings, reversing detection, and cyclist/pedestrian alert systems as of July 2024, with full compliance for all new registrations to follow. London’s Direct Vision Standard tightened requirements in 2024, pushing urban operators toward better cab visibility and side detection. In the U.S., electronic stability control has been mandatory on most heavy tractors since 2017, and a federal rulemaking to require AEB on heavy trucks is advancing alongside updated test protocols.

Today, equipment makers are aligning with UNECE standards such as BSIS and MOIS to harmonize performance across markets. The technology stack is maturing fast. Radar-and-camera fusion underpins today’s AEB, which ties into electronic braking systems to shorten stopping distances and mitigate rear-end collisions—an area where studies have shown sizable reductions for equipped fleets. Lane-keeping and road-edge detection help on rural highways, while intelligent speed assistance blends map data with sign recognition to curb inadvertent speeding.

Digital mirror systems and 360-degree vision reduce blind spots around cabs and trailers, particularly on the passenger side where vulnerable road users are hardest to see. OEMs say these features ship as standard or popular options on new tractors today, with calibration tools that account for trailer length and articulation. In day-to-day operations, connected safety is doing quiet work behind the scenes. Driver-monitoring cameras flag distraction and drowsiness for real-time coaching without overwhelming operators, and cloud analytics surface hotspots like recurring hard-brake zones near busy interchanges.

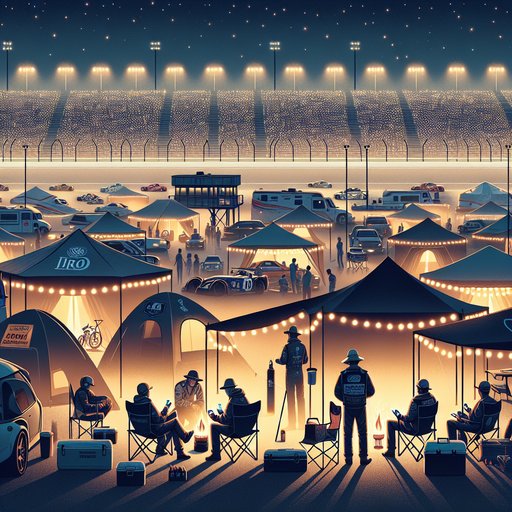

Tire-pressure monitoring and automatic inflation cut blowouts and keep stopping performance consistent, while brake wear and temperature sensors warn of fade on mountain descents. Geofenced speed limits in depots and work zones are reducing yard incidents, and predictive cruise with downhill speed control is helping balance safety with fuel efficiency. Over the past year, large fleets report measurable drops in harsh-braking alerts and fewer rear-end contacts in dense traffic. Proving grounds include both test tracks and the paddock.

Truck racing series have pushed advances in brake cooling, thermal monitoring, and high-visibility lighting that inform production hardware and software safeguards. Meanwhile, V2X pilots on corridors such as Germany’s A9 and Michigan’s I‑94 are delivering early warnings for queuing traffic, low bridges, and work zones that trucks can act on automatically. Trailer safety is also catching up, with roll-stability and side-detection packages moving from premium options toward standard specifications on new reefers and curtain-siders. Over the next 12–24 months, expect broader AEB fitment on vocational models, more precise cyclist detection in cities, and tighter integration between tractor and trailer sensors to close the remaining gaps.