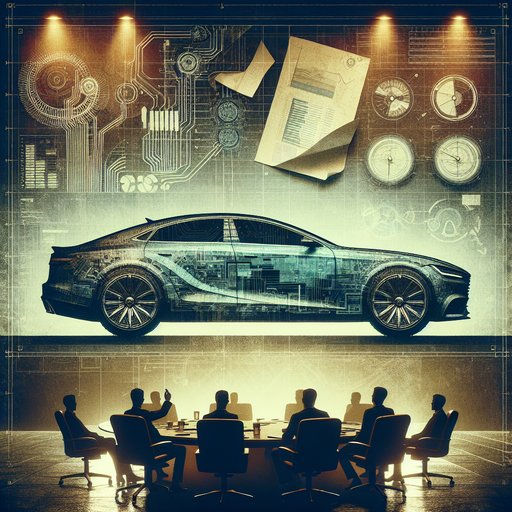

Digital twin simulations—high-fidelity, living models of vehicles, factories, and workflows—are reshaping how cars are conceived, built, and verified. In 2025, automaker design studios are using them to iterate on surfaces and fit-and-finish with the same care a sculptor brings to clay, while production teams trial robot choreography and tooling virtually before metal is cut. Museums and design institutions are beginning to showcase these visual systems to broader audiences, helping demystify how craft and code now intersect on the factory floor. The immediate result is fewer surprises during launch, tighter quality loops, and a clearer thread between the artist’s intent in the studio and the car customers experience on the road.

In design studios, digital twins let modelers, exterior stylists, and UX artists explore light, texture, and assembly tolerances in one shared canvas, long before a physical buck is milled. Curators at design schools and institutions have leveraged these interactive models in lectures and installations to show audiences how subtle line changes ripple into manufacturability. That public framing matters: it grounds computational precision in the language of craft, making the work legible beyond engineering. Over the past year, several studios have opened virtual “walkthroughs” for clients and press, turning iterative decision-making into an exhibit rather than a black box.

On the factory side, virtual commissioning has become the new rehearsal stage, where robots, conveyors, and human workflows are blocked out like a performance before opening night. Production artists—toolmakers, weld specialists, paint finishers—now test sequences in the twin to expose collisions, idle time, and ergonomic strain. Institutions such as company museums and visitor centers have begun highlighting these live simulations, giving local communities a window into how launches are stabilized. The practical impact is immediate: fewer line restarts, faster ramp-ups, and reduced scrap when SOP arrives.

Quality control is seeing the sharpest shift as vision systems train on twin-generated data, spotting defects that are rare in the real world but common in simulation. Inspectors use AR overlays derived from the twin to compare each body panel or seam with the studio’s source geometry, closing the loop between aesthetic intent and measurable tolerance. When a deviation appears, the digital thread ties it back to a specific process step, enabling rapid root-cause analysis rather than broad rework. For audiences in galleries and open-house tours, these visual QC stories translate abstract analytics into something you can see and understand.

Looking ahead, artists-in-residence programs inside factories and labs are helping humanize these tools, turning complex dashboards into narratives that workers and visitors can navigate. Curators and corporate archivists are starting to preserve simulation scenes alongside clay models and sketches, acknowledging twins as design artifacts in their own right. As standards mature this year, interoperability between studio twins and shop-floor twins should become more seamless, strengthening traceability from concept to car. For collectors, educators, and the public, that continuity offers a new way to witness quality—an evolving exhibition where every build is both performance and proof.